|

|

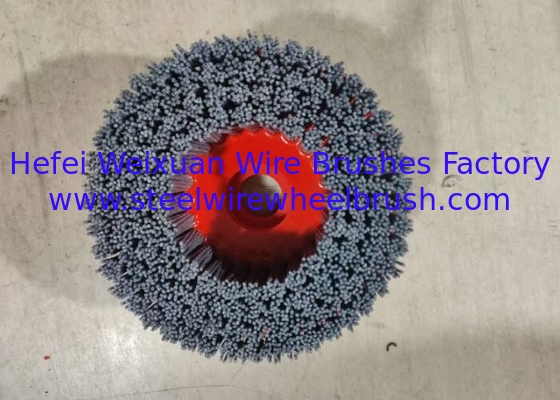

Customizable 150mm Abrasive Nylox Rotary Deburring Brushes for Sheet Metal

Product Details:

Payment & Shipping Terms:

|

| Item Name: | Nylox Rotary Deburring Brushes | OD: | 150MM |

|---|---|---|---|

| ID: | 25.4MM | Bristle Trim Length: | 25mm |

| Base Thickness: | 20mm | Base Color: | Red |

| Material: | SIC | Sandpaper Grits: | 500 |

Customizable 150mm Abrasive Nylox Rotary Deburring Brushes for Sheet Metal

1. Abrasive Disc Brushes are composed of hard-wearing abrasive nylon filaments bonded to a fibre reinforced thermoplastic base.

2. These abrasive disc brushes materials can be ceramic, diamond, silicon carbide abrasives, aluminum oxide abrasives that produce maximum burr removal rates and provides optimum surface finishing effect.

3. We have 2 styles disc brushes: Dot style and Turbine style. Dot style usually for general purpose deburring and surface finish applications and the Turbine style brush is good in medium and heavy deburring applications.

4. Abrasive grains are embedded in the entire length of the bristles so the sides act like flexible files. These brushes remove workpiece material as well as surface contamination in a single step.

5. The nylon bristles do not scratch and are appropriate for cleaning and wood polishing, stainless steel and aluminium treatment.

6.These disc brushes won't leave behind debris that could cause rust on your workpiece. Also they are good for acids and alkalies application.

![]()

Application Industry

- woodworking

- electronics

- engine block

- cylinder

- pneumatic part

- hydraulic part

- hardware

Dimensions:

|

Outer Diameter

|

150mm |

|

ID diameter

|

25.4mm |

|

Base thickness

|

20MM |

|

Bristle height

|

20mm |

|

grits

|

120 grits |

![]()

Full Sector:

1. Big sector brushes are heavily filled with filaments, used for heavy duty application where radiusing is not required or less required.

2. Only Face DeBurring.

3. Toughest in the whole range but require lots of coolant or water supply.

4. Cost – effective, longer life and less cycle duration required

5. Can be made more aggressive by opting for flat filaments instead or round filaments

6. Ideal for Heavy DeBurring.

Vertical Sector:

1. The vertical Sector compensates for the need for a planetary head machine.

2. Space between two slots help easy swaying moments of the filament.

3. Covers wide surface area and therefore gives Fast out-put and longer life.

Circular Sector:

Only brush useful for planetary action

Goes with linear movement ( side to side) of the head but not with straight up and down movement of the head

Heavy Sector:

1. Heavy-sector application – edge deburring and surface finishing esp. for medium to heavy job

2. Restricted for small holes and cut-outs

3. Cost-effective with less cycle timing compared to CS

4. Two variants –

One circle – available in small dia.

Two circles: More aggressive with better cutting action and life.

5. Available in larger brush diameter

6. Ideal for Medium to Heavy DeBurring.

![]()

![]()

Application:

Medium DeBurring for Class II and Class III types of Burr’s.

Edge Radiusing / Rounding and DeBurring Surfaces

Good for Flat surfaces – where all burr’s are in one plane.

Industry: Engineering, Automobile, Aeronautic, Turbine.

-

Truck And Automotive Rims Aluminum Wheel Deburring Brush With 460 Mm OD

-

Composite Disc Silicon Carbide Brush / Abrasive Filament Brushes High Density

-

Metal Base CNC Deburring Brushes / Nylon Abrasive Filament Brushes With Locating Hole

-

Flat Surface CNC Deburring Brushes 120 Grit Aluminum Oxide Bristle Material

-

Industrial Disk Abrasive Deburring Brush Custom Size Easy Installation For Moulds

-

Silicon Carbide Filament Abrasive Disc Brushes 150mm OD With 6mm Shank